It has been quite a while since I have written anything technical about bikes. This is largely a result of the fact that for the first time since I started cycling again as an adult I have been relatively happy with my bikes and their configurations, which has left me free of my usual desire to acquire shiny new bicycle parts. However, this state of relative satisfaction with the bikes does not mean that things don’t occasionally wear out or break. Last week I noticed a familiar clicking sound coming from the rear hub of the Brompton.

I have written previously in reasonable detail about the Servicing the Sturmey Archer AW hub. The BWR hub used in the six-speed Bromptons is also a three speed hub gear made by Sturmey Archer, so I thought I would show how the BWR compares to the pictures I took of the 1976 AW hub for the aforementioned post.

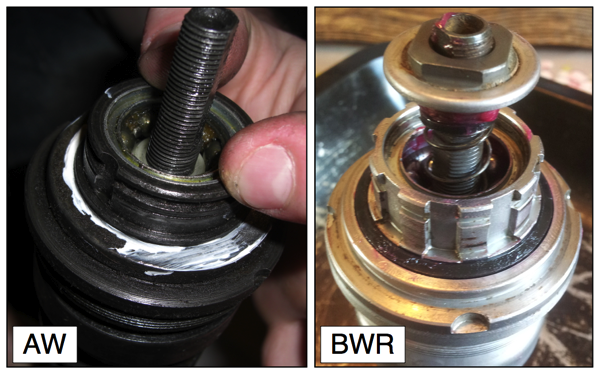

The planet cage differs significantly between the old AW hub and the BWR. The planet cage on the AW sits on top (drive side) of the sun pinion and can be simply lifted off during disassembly. This is also the case with the new AW and S-RF3 hubs without the ‘intermediate gear’ (sometimes referred to as NIG versions). The BWR differs in that the planet cage is split into two pieces, the bottom of which slides on from the bottom (non-drive side) and the top slides on from the top (drive side) and is fixed onto the bottom piece with the 4 M3 cap head screws shown in the picture above. The result of this is that the planet cage is stuck on the sun pinion. I decided not to disassemble to two-part planet cage as the first screw I tried to loosen was very stiff and it didn’t seem worth risking snapping the screw for this job. The low gear pawls seen at the bottom of the planet cage on the BWR are similar to those on the NIG AW and S-RF3 hubs (which are also retained with a circlip). These pawls are what produces the characteristic ‘tick-tick-tick’ of Sturmey Archer three speeds in their second and third gears.

The planets of the BWR have 12 teeth and revolve around a 34-tooth sun pinion, which produces wider-spaced gearing than the AW which has 20-tooth planet and 20 tooth sun pinion. These smaller planets require smaller pins than the standard range three-speed hub.

The clutch of the BWR differs noticeably from that of the old AW, but is the same as in the NIG AW and S-RF3 hubs. The axle key is fitted in the slot underneath the clutch in this shot (not fitted in the picture of the AW) and is also the same as in the new standard range hubs.

The gear ring has 60 teeth in the old AW, new NIG hubs and BWR. The differences between the 1976 AW hub and the BWR shown are largely superficial. The easily lost wire pawl springs are still used in the BWR gear ring. The gear ring pawls are disengaged in first gear, which is why there is no characteristic ‘tick-tick-tick’ sound.

The ball ring is another part which has changed little between the old AW and BWR shown. The only major difference appears to be the addition of two extra notches for removing the hub internals using a C-spanner or hammer and punch. The AW ball ring has a metal dust/bearing retaining cap which has been replaced in the more modern hubs with a plastic retaining ring for the ball bearings.

Here we can see the difference between the driver of the old AW hub and that of the BWR. Whilst the AW is designed to take a single three-splined sprocket, the BWR is designed to take a pair of Shimano-style nine-splined sprockets. Like the clutch, the internal portion of the driver was changed between the old AW and the new NIG AW, S-RF3 and BWR in order to fix the issue of the ‘intermediate gear.’ Other than being extended and having a different spline pattern for the two-speed cassette, the BWR driver is the same as that used in the NIG AW and S-RF3.

Aside for the problem of water ingress, the driver was where I found the source of the problem I was having with the BWR hub; the bearing surfaces on the driver and cone nut had some pitting on them. This is an issue I have had with every variant of the Sturmey Archer NIG three-speed hub, but oddly never the old AW. This does not seem to be a problem which afflicts other people with the same frequency and may be a result of the way I ride or the conditions my bikes are subjected to.

Thankfully in the past I have been able to order a replacement driver from SJS Cycles (who stock a great range of Sturmey Archer hub spares) but I could not find the BWR driver (Sturmey Archer part number: HSA800) on their site. I emailed SJS to enquire about this part and was told that Brompton only issue them for service, in order to be supplied with a replacement driver from Brompton you need to send the old one back to them. I was quite surprised by this; as my primary means of transportation I can’t afford to have my Brompton out of action for the sort of time required to perform such an exchange. If I lived somewhere with a Brompton dealer who did Brompton servicing in a meaningful way (i.e. not Chester) perhaps there would be a better way of doing this, but here in Chester I would have to go through The Bike Factory who do not keep Brompton spares in stock.

I am not sure why Brompton has chosen to restrict the supply of BWR replacement parts. Outside of a big city with a selection of Brompton dealers, in order to be able to depend on a bicycle with this hub there needs to be a supply of spare parts available. I doubt that Brompton are selling the BWR driver at a loss, so even if some of them went to tinkerers and enthusiasts (e.g. turning a S-RF5 into a ten-speed on a Brompton) it would not be detrimental to their business. It is a truly baffling move by Brompton which serves only to make the BWR a less viable option for people like me. Whilst decades-old AW hubs still have spare parts readily available, I am not sure that I will be able to fix this BWR hub up as easily as the 36 year-old AW shown in the pictures above, and that leaves me a bit disappointed in Brompton.

![20120416_192127[1]](https://chestercycling.wordpress.com/wp-content/uploads/2012/04/20120416_1921271.jpg?w=584&h=438)

![20120416_192057[1]](https://chestercycling.wordpress.com/wp-content/uploads/2012/04/20120416_1920571.jpg?w=584&h=438)

![20120416_191953[1]](https://chestercycling.wordpress.com/wp-content/uploads/2012/04/20120416_1919531.jpg?w=584&h=438)

![20120416_192001[1]](https://chestercycling.wordpress.com/wp-content/uploads/2012/04/20120416_1920011.jpg?w=584&h=438)